Mist Eliminator

HIGH CAPACITY MIST ELIMINATOR - POLISHING VESSEL

LIQUIDS CARRYOVER ELIMINATION FOR HIGH LIQUID LOADS

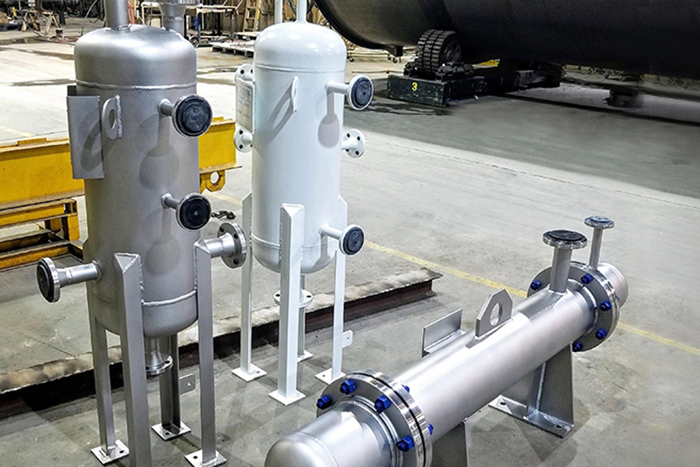

TransTech's ground breaking Polishing Vessel, configured with cutting edge, high performance internals, is a high capacity, high efficiency demisting device that sets a new standard in liquids carryover elimination.

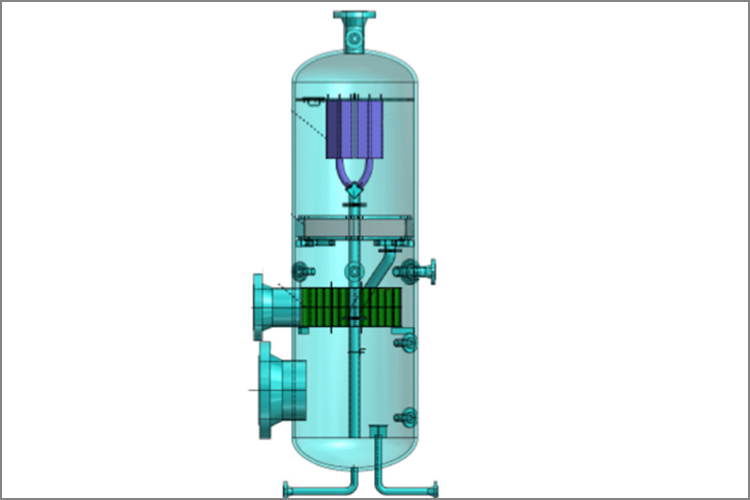

Our systematic design approach brings together a high-performance vane inlet device (AMACS Accuflow™ Inlet Diffuser) for bulk liquids removal, followed by a mesh or vane agglomerator, and final polishing by a state-of-the-art AMACS MAXSWIRL™ Cyclone device which uses centrifugal motion to provide exceptional separation results.

Defined by performance that is at once both remarkably effective and unexpectedly economical, TransTech's polishing vessels are the definitive solution for minimizing liquid carryover in the presense of high liquid/vapor loads.

TYPICAL APPLICATIONS

- Gas/liquid separation for upstream, midstream & downstream

- High pressure services

- Debottlenecking

- Retrofit

- Revamp

BENEFITS

- High performance in high pressure applications

- Readily handles large liquid volumes

- Higher capacity than Mesh and Vane Mist Eliminator - allowing for smaller vessel size.

- Vertical and horizontal orientation options

- Vertical orientation configuration offers footprint advantages

- Less sensitive to gas maldistribution

- No rotating parts - minimized maintenance

- Higher operating ranges can be accommodated - without affecting efficiencies

OPTIMIZED SOLUTIONS

TransTech's Polishing Vessels are extraordinarily effective in high-pressure systems in both upstream and downstream applications. Due to its high capacity and efficiency, this equipment brings a new level of optimization to newly built vessel designs as well as for troubleshooting and solving existing operational problems and retrofit projects.

TransTech Polishing Vessels are available in both horizontal and vertical orientation for upstream and downstream applications, including:

- All High Pressure Scrubber/Separator Applications.

- Places wherein incoming liquid flow is high and high quantitative liquid separation (gross separation) efficiency is required

- Inlet Separator

- Gas Plant

- Before and After Dehy units (associated with high pressure)

- Before and After Amine units (associated with high pressure)

- Compression stations.

- LNG Plants

- FPSO

- Chemical Plants (before dryer beds)

- Cold Separators

- NGL Plants

- Compressor Suction Scrubbers (high pressure)

- FPSO

- Compressor Stations.

- Gas Lift Suction Scrubbers

- High Pressure Discharge Scrubbers

A New Standard in Mist Elimination - with Proven Results.

The MAXSWIRL™ Cyclone internal is a robust welded design -- with fixed elements that virtually eliminate maintenance.

This device has been rigorously tested in high pressure systems, including a wide range of liquid and vapor rates, with varied hydrocarbons. Due to its high capacity and efficiency, MAXSWIRL™ Cyclone can provide optimized solutions for new bulit vessel designs as well as troubleshooting and solving existing operation problems and retrofit projects.

CONTACT US

Call us today to speak with one of our Mist Elimination experts:: 1-888-206-4563 —or click to contact us below:

.png)

FREE Sample Project

Let us share similar scope project specs with you! Request a sample project similar in scope to your current needs to receive:

- A complete sample project budget

- Sample P&ID

- Project Schedule

- Project Quote

- More...