Mol Sieve (MSDU)

Fabrication

Mol Sieve (MSDU) Fabrication

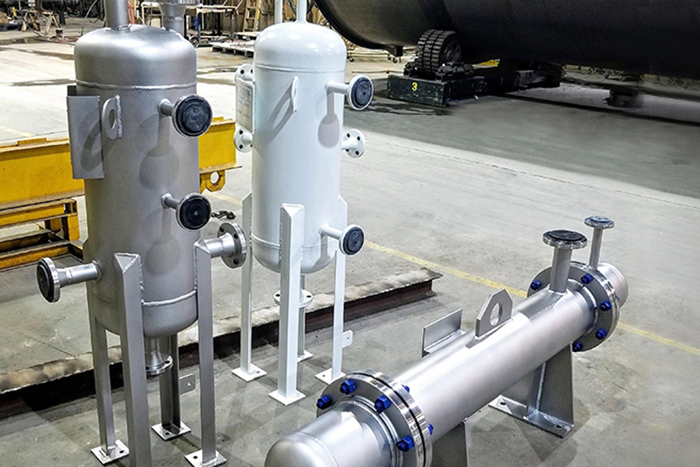

CUSTOM FABRICATED MOLECULAR SIEVE DEHYDRATION UNITS

TransTech's custom fabricated Molecular Sieve Dehydration Units (‘Mol Sieves’) utilize solid molecular sieve desiccants to effectively remove water (and in some cases H2S) from the natural gas stream—preventing hydrate formation and corrosion in downstream equipment.

SUPERIOR DRYING RESULTS

Favored in applications that demand superior drying results, our Mol Sieves eliminate water vapor to 0.1 ppm( and lower) and areideal for preparing the gas stream for use in cryogenic applications. Additionally, our Mol Sieve Units can accommodate higher inlet gas temperatures and large flow variations, making them robust and flexible solutions for an array of needs. Indeed, Mol Sieve Units are also commonly found upstream of NGL extraction plants and LNG plants.

EFFICIENT, CONTINUOUS OPERATION

Our Molecular Sieve Units utilize multiple molecular sieve beds to support continuous operations by rotating beds through a fixed cycle of adsorption (treating) and desorption (regenerating). As beds become saturated, they are heated to remove the impurities adsorbed on the molecular sieve during the treating phase.

Our standard MSDU package includes two or more matching mol sieve units. In our simplest two-unit design, one of these units operates in treating mode with the other in regeneration mode. Once the unit in treating mode becomes saturated, it reverts to regeneration mode while the freshly regenerated unit becomes active in treating mode.

FEATURES & BENEFITS

- Standard, semi-custom, and custom packaged units

- Steel and carbon steel vessel construction

- National Board registered & stamped

- Conformance with NACE MR-01-75

- High efficiency inlet separator

- Adsorption towers

- Mol sieve beds

- Regeneration Gas Heater

- Regeneration Gas Cooler

- Regeneration Gas Separator

- Dry gas dust filters

- Interconnecting Piping

- Valving & instrumentation

- Removes water vapor from natural gas streams to < 0.1 ppm and more

- H2S removal from the natural gas stream in some applications

- Increases Downstream Equipment LIfe

- Conditions the natural gas stream for use in cryogenic applications

- Reduces risk of hydrate formation

- Optimized bed design for maximum efficiency

- Reduces foul gas odors

- Sales gas metering

- Automated switching valves for continuous operations

- Single or multi-skid mounted for mobility and ease of installation

Backed by over five decades serving the oil and gas industries, TransTech has extensive experience designing and manufacturing specialty packaged equipment for a broad range of gas processing and treating applications.

With our expert in-house design, engineering and fabrication teams, we can build your molecular sieve dehydration unit to your exact specifications; customize one of our standard designs to suit your operations—and save you money; or deliver one of our time-tested standard designs for the greatest economy and fastest delivery.

With our own 160,000 square foot fabrication facility, we can also readily package hybrid solutions to address a wide range of gas processing needs.

END-TO-END SERVICES

From conceptual design to installation, startup and commissioning, we have the engineering expertise along with fabrication, site installation, startup and commissioning know-how to ensure seamless execution of your project.

CAPABILITIES INCLUDE:

- ASME S, U, U2, U3, PP and R certifications

- Custom fabrication of oil & gas process vessels, production equipment

- Turnkey logistics support from heavy hauling to vessel installation

- Seasoned engineering design team

CONTACT US

Call us today to speak with one of our mol sieve dehydration unit experts: 1-888-206-4563 —or click to contact us below:

.png)

FREE Sample Project

Let us share similar scope project specs with you! Request a sample project similar in scope to your current needs to receive:

- A complete sample project budget

- Sample P&ID

- Project Schedule

- Project Quote

- More...